News

Is your forging press really performing at its best?

Within a forging press, countless details will determine the success of the entire process. A slightly uneven layer of release agent, minor temperature shifts, or misaligned components may go unnoticed during production, yet can lead to increased tool wear, higher scrap rates, or inconsistent part quality.

Read more … Is your forging press really performing at its best?

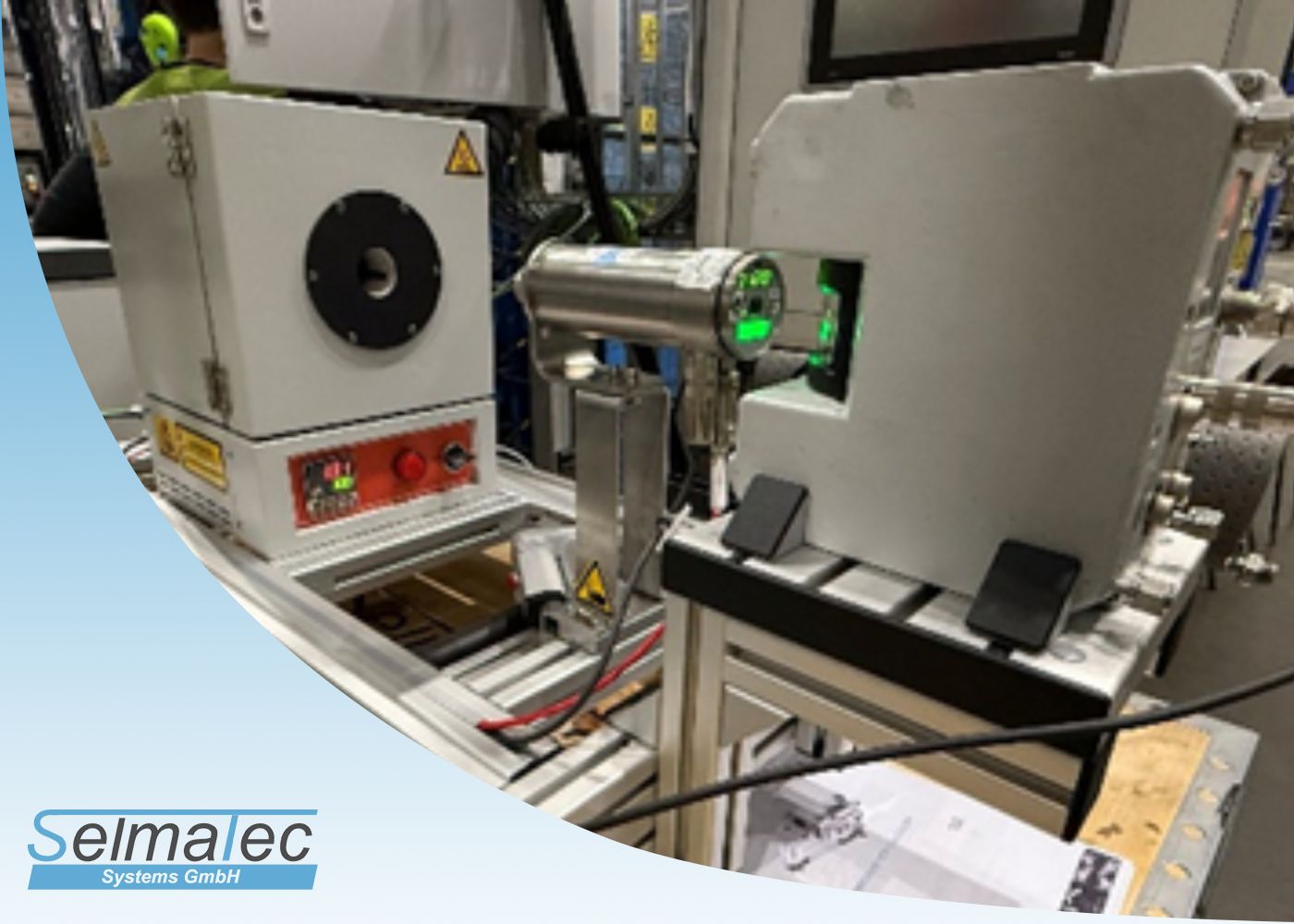

Calibrating with Selmatec just became easier! Discover our remote calibration kit for IR devices

Keep your inline infrared monitoring accurate with our CQI-9-compliant remote calibration for IR devices. This service is fully compatible with our PH-Inspector for hot stamping/press hardening lines, as well as other Selmatec solutions, ensuring precise measurements—without downtime.

Keep your inline infrared monitoring accurate with our CQI-9-compliant remote calibration for IR devices. This service is fully compatible with our PH-Inspector for hot stamping/press hardening lines, as well as other Selmatec solutions, ensuring precise measurements—without downtime.

Slag carryover and unreliable material separation is costing more than you think. Control it in real time!

Slag carryover during tapping is a well-known challenge in steelmaking, often invisible in real time, yet highly impactful on quality, equipment, and process stability. When separating precious metals, unreliable slag removal can also lead to costly material waste.

What if the next failure in your battery line is already happening and you can’t see it?

Battery manufacturing is one of the most dangerous processes due to anomalies that can escalate quickly into explosive scenarios. With our BM-Inspector, we want to ensure traceability and we aim to push monitoring limits to ensure your team gets the maximum reaction time to prevent catastrophic events

Read more … What if the next failure in your battery line is already happening and you can’t see it?

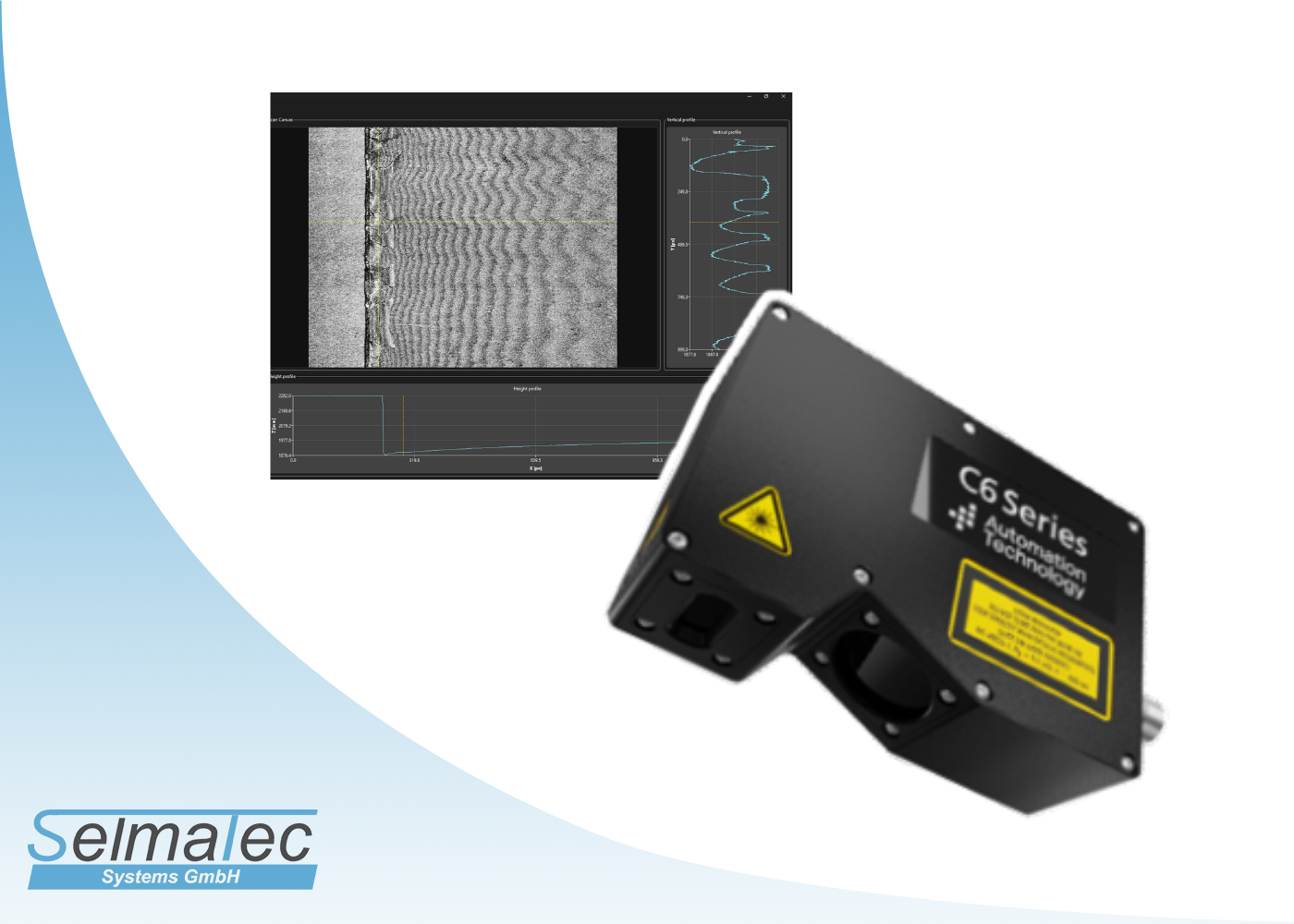

Inline high-speed 3D Edge Inspection: Safer, More Reliable Steel Processing

Edges define steel quality, safety, and process reliability. See what you’ve been missing with our new SE-Inspector solution based on 3D laser sensor C6 series.

Read more … Inline high-speed 3D Edge Inspection: Safer, More Reliable Steel Processing

Extreme heat, dust and debris inflict constant stress on your devices. This is why safeguarding them is a constant challenge.

In our search to perfect our solutions, we now offer an upgrade to our protective design for the line scanner, ideal for current users of the PH-Inspector and other systems that operate in demanding production environments.

Investing in Kiln Blaster: A Roadmap to Modernize Rotary Kiln Operations and Cut Costs with Efficient Exhaust Gas Monitoring

With industries shifting toward predictive maintenance and energy-intelligent control, the Kiln Blaster aligns effortlessly with modernization priorities business owners are looking out for 2026.

Traceability starts with visibility. Here’s how Selmatec delivers with the LED StripE

Behind every fast production line is a constant struggle engineers know well: keeping visual traceability reliable. Selmatec answers with the patented LED StripE, our Efficient industrial-grade solution carefully built to follow each product, marking good ones, flagging bad ones.

Read more … Traceability starts with visibility. Here’s how Selmatec delivers with the LED StripE

High-speed monitoring feedback will transform your business. Are you ready for it?

Business owners in the food industry face the same core challenges to avoid extra waste, complaints and costly recalls. If you’re aiming for higher product consistency, food safety, and process reliability, this Selmatec solution is ready to improve your business.

Read more … High-speed monitoring feedback will transform your business. Are you ready for it?

Different emissivity requires extra attention! Start revealing now what conventional sensors miss

Hot spots, uneven thickness, and holes challenge every plastic manufacturer. With the MP300 Line Scanner and Thermalert 4.0 pyrometer, you can stay at the forefront of innovation in the plastic industry.