News

RF-Inspector: Your real-time furnace companion for safer operations

The ability to monitor conditions inside a furnace, where critical failures often begin, has historically been limited. At Selmatec, we aim to address this gap with our RF-Inspector, a robust, real-time monitoring system designed specifically for harsh furnace environments.

Read more … RF-Inspector: Your real-time furnace companion for safer operations

A Robust and resilient build: Endurance Series Pyrometer

Whether you’re working with metals, glass or cement, the Endurance is a customer-favourite device that not only surprises with its incredible flexibility, but also withstands harsh environments.

Read more … A Robust and resilient build: Endurance Series Pyrometer

CL-Inspector: A highly targeted answer to ladle monitoring during casting

Using the same high-performance hardware as our trusted LA-Inspector system, this new specialized thermal monitoring system is intended for use when the ladle is in casting position on the trolley.

Read more … CL-Inspector: A highly targeted answer to ladle monitoring during casting

Data is the raw material of the future: Find out with our CS400 Software for Kiln Monitoring

Every day there are new methods to keep pushing the limits of efficiency and accuracy in kiln monitoring. Thanks to our partner Fluke Process Instruments, we provide an answer to these demanding times.

CB-Inspector: Eliminate all uncertainties in billet monitoring and handling

With advanced infrared technology, real-time process transparency, and customizable coverage, our system not only helps prevent errors but also enhances safety by protecting equipment and reducing the risk of hazardous situations.

Read more … CB-Inspector: Eliminate all uncertainties in billet monitoring and handling

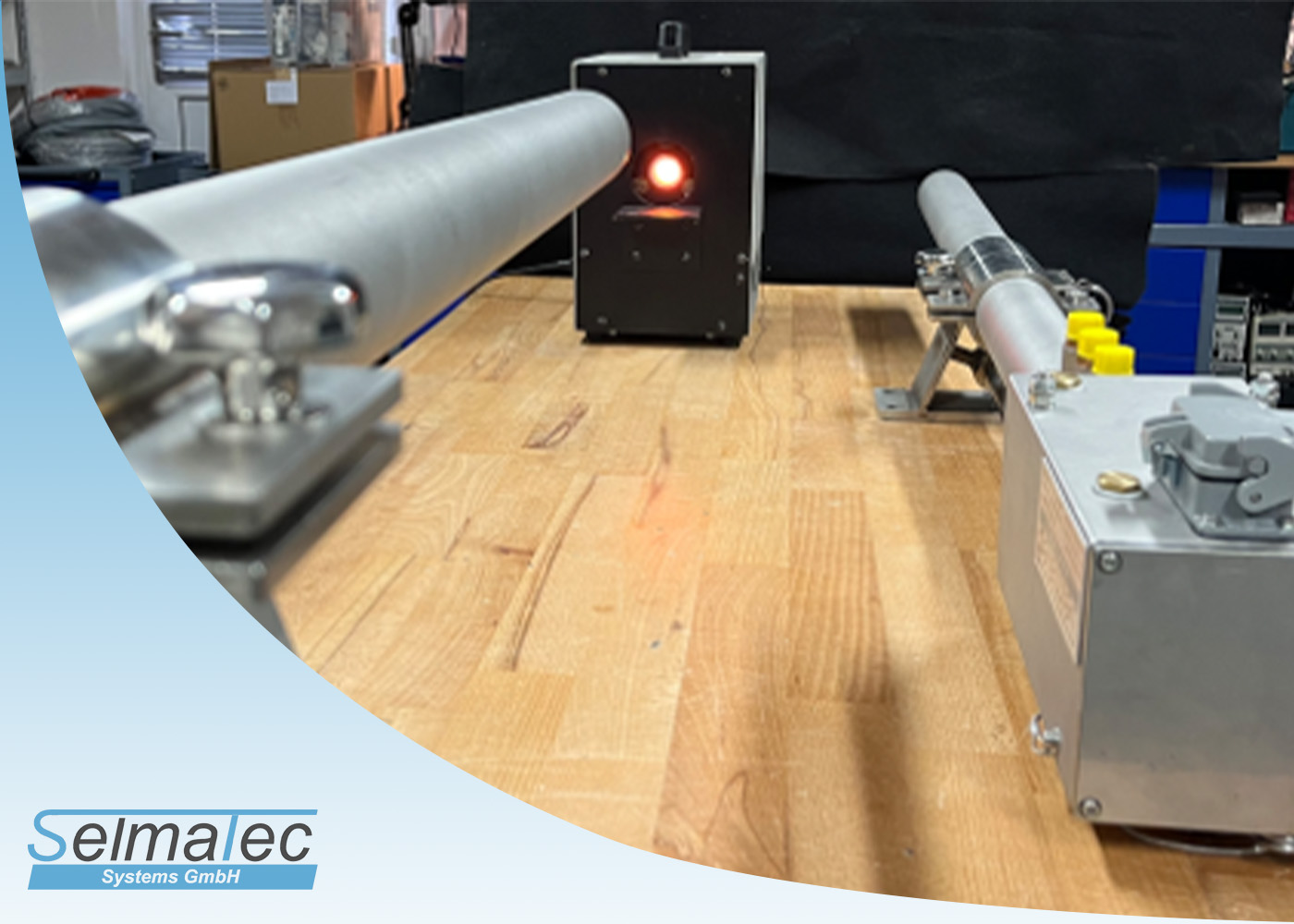

LED StripE: The Selmatec Solution to visual clarity in industrial plants

Traditional LED strips lack the optimized set-up that we configured for your convenience. In contrast, Selmatec’s patented LED StripE is designed to improve efficiency, visibility, tracking, and manual quality control.

Read more … LED StripE: The Selmatec Solution to visual clarity in industrial plants

Technology evolves fast...so should your monitoring system!

Get off to an inexpensive start with a scalable solution for hot stamping lines, and don’t let outdated systems hold you back.

Read more … Technology evolves fast...so should your monitoring system!

Want to ensure only quality products leave your production line? Try our DC-Inspector today!

Monitor the forming results of cold forming lines for sheet metal with our third-generation AI-controlled DC-Inspector. Detect small defects like waviness or cracks, which are usually unnoticed and lead to compromised product quality.

See beyond the heat: Smarter monitoring for extreme environments with the FC-Inspector

Meet the AI powered FC-Inspector. Designed for temperatures up to 1,600°C, it delivers live video, AI-driven analysis, and automated process optimization. Durable, intelligent, and of easy installation, it is the next step in smart industrial monitoring.

Read more … See beyond the heat: Smarter monitoring for extreme environments with the FC-Inspector

Protect Your Plant and Workforce with Safe Handling and Magnetic Lifting Using Our IR 2D Scan

Temperature control in the cooling bed is vital to maintaining both product quality and safety, but a simple inaccuracy can cause expensive downtime and safety hazards. Maximize the capabilities of the MP Line Scanner with a tilt unit for wider and more thorough coverage.